The Impact of Automation on Modern Production Processes

Automation has revolutionized the way industries operate, transforming traditional production processes into streamlined, efficient systems. With the advancements in technology, machines are replacing manual labor, resulting in increased productivity, reduced labor costs, and improved overall quality. This blog post explores the impact of automation on modern production processes and how it has shaped industries in recent years.

One of the most significant benefits of automation in production processes is the increased productivity it offers. Machines are capable of working continuously without breaks or rest, ramping up production rates significantly. By automating tasks, companies can produce more goods in a shorter amount of time, leading to increased output and profitability. In addition, with automation, manufacturers can achieve faster turnaround times, satisfying customer demands in a timely manner. This allows businesses to stay competitive in a rapidly changing market.

When considering the impact of automation on production processes, it is impossible to ignore the cost-effectiveness it brings. While initially requiring a significant investment, the long-term benefits outweigh the initial cost. Automated machines eliminate the need for manual labor, reducing the number of employees required for a task. This results in substantial savings on labor costs, making production processes significantly cheaper. Moreover, automation minimizes the likelihood of human error, reducing waste and further cutting costs. Businesses that adopt automation can allocate their resources more efficiently, investing in other aspects of the company’s growth and development.

Another notable impact of automation on modern production processes is the improvement in overall quality. Machines are programmed to perform tasks with exceptional accuracy and precision, ensuring consistent standards throughout the production line. This eliminates variations caused by human error and reduces the likelihood of defects or faulty products. The integration of sensors and advanced monitoring systems allows companies to closely monitor every stage of production, ensuring adherence to quality control measures. The result is a higher-quality product that meets or exceeds customer expectations, enhancing brand reputation and customer satisfaction.

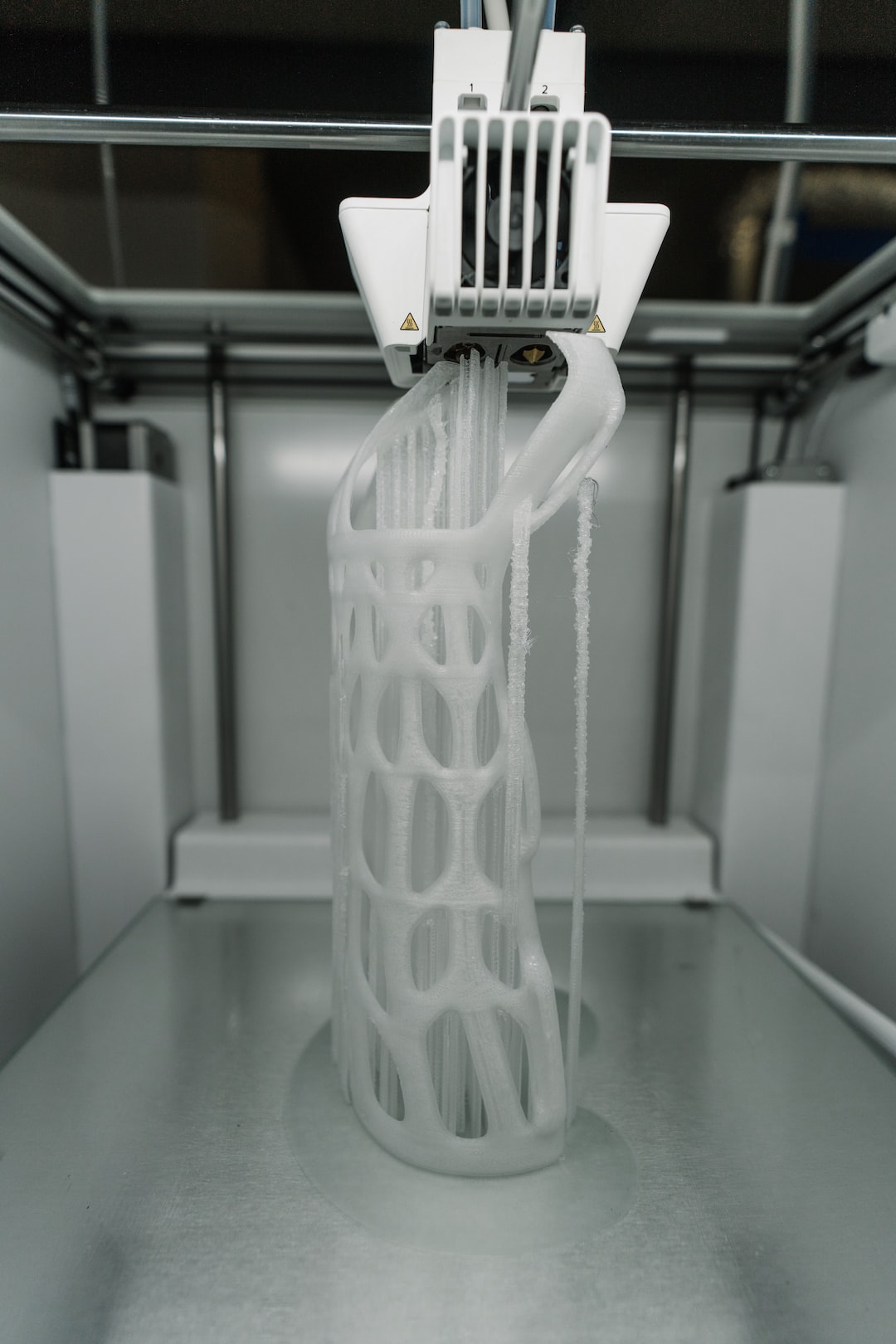

Automation also allows for the customization and personalization of products on a larger scale. With the ability to program machines to adapt to specific requirements, manufacturers can easily produce customized products tailored to individual customer preferences. This level of customization was previously time-consuming and expensive, but automation has made it more accessible. This shift in production processes has also led to the rise of mass customization, where companies can offer a wide range of variations, enabling customers to personalize their products without sacrificing efficiency or increasing costs.

Although automation brings numerous benefits to production processes, it does raise concerns about the displacement of human workers. As machines take over repetitive and mundane tasks, jobs that were once done by humans become obsolete. However, it is important to note that automation leads to the creation of new job opportunities. While some roles may be replaced, new positions emerge to operate and maintain automated systems. Additionally, the efficiency and cost-effectiveness of automation allow companies to expand their operations, creating more job opportunities in other areas. It is crucial for businesses to invest in upskilling and reskilling their workforce to adapt to these new opportunities.

In conclusion, automation has had a profound impact on modern production processes. Its ability to boost productivity, reduce costs, improve quality, and facilitate customization has transformed industries across the globe. While concerns about job displacement exist, it is important to recognize the new opportunities that arise with automation. As technology continues to evolve, the integration of automation will become even more crucial in driving the success and competitiveness of businesses.